At Unit 2, TEPCO still expects to begin removing fuel from the spent fuel pool sometime in FY23 (April 2023 to March 2024). Now, given the reduced radiation levels inside the operating floor of the reactor building found in investigations conducted over the winter, TEPCO is also considering a third approach to the removal, in addition to two approaches that both involve demolishing the upper part of the operating floor.

In the new approach, only as little of the floor as possible would be removed, with an assembly base for removal work to be built on the south side of the operating floor, allowing access to the inside of the floor.

At a press conference, President Akira Ono of the Fukushima Daiichi Decontamination & Decommissioning Engineering Company explained the new thinking. The Unit 2 reactor building, he said, had been spared an internal hydrogen explosion, and by making proper use of it now, the risk of release of radioactive materials can be substantially controlled.

Moving forward, the three fuel-removal approaches will be evaluated in a comprehensive manner considering such matters as dust-suppression measures, the reduction in workers’ exposure doses, rainwater measures, and the influences on other decommissioning work. TEPCO will make its choice of the final approach by the end of FY19 (March 31, 2020).

Although the dismantling of the exhaust stack for Units 1 and 2—part of efforts to improve the surrounding environment—was to have been launched on May 20, it ended up being postponed two months. During the verification process that took place after the crane was assembled, the distance between the crane’s hook and the top of the stack was found to be different from what was planned. To ensure the suspension height, the sub-base needs to be altered, necessitating the two months’ delay.

In way of explanation, President Ono cited several factors, including failures in the division of roles among partner companies, and those involving checking procedures at the site, among others. The work is now expected to start around the end of July and finish in the fourth quarter of FY19 (namely, January to March 2020). He said that TEPCO intended to carry out the process safety and steadily from now on.

In another piece of news, as part of an effort to improve its emergency responses, TEPCO temporarily stopped injecting water into Unit 2 on May 13 in a short test to reconfirm that the temperatures at the bottom of the reactor pressure vessel (RPV) would generally remain within a predicted range. Meanwhile, sampling has been proceeding inside of the containment vessels at Units 1 to 3.

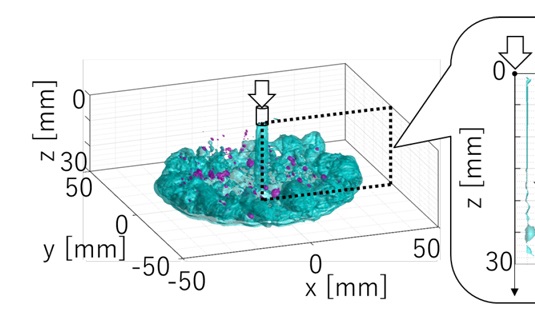

According to particle analyses by electron microscopes focusing on uranium, carried out during the previous fiscal year (April 2018 to March 2019), two types of particles were identified: particles containing almost no zirconium, which are used for fuel cladding, and particles containing substantial zirconium. That information will contribute to analyses of fuel debris samples, as well as to a determination of how to deal with it.