The two selected themes are:

-

Development of innovative safety technologies for next-generation reactors (Aug. 2025 – Feb. 2026)

-

Technology development and demonstration of supply capacity for realizing the iBR (Aug. 2025 – Jan. 2028)

The first will focus on the development of advanced safety features such as a double-cylinder containment vessel, high-performance valves, additional countermeasures, and verification of analytical codes. The second will demonstrate the feasibility of iBR through improved core materials and component manufacturing using Additive Manufacturing (AM) technology, aiming to establish both technical viability and a robust supply chain.

The iBR—short for innovative, intelligent, inexpensive boiling water reactor—is a next-generation BWR (800–1,600 MWe) uniquely developed by Toshiba. Its defining characteristic is the promise of “no need for long-term evacuation or relocation even in the event of a severe accident.” The design ensures a seven-day grace period (no operator intervention required) without external support, positioning the iBR as a “reactor that can coexist with local communities.” Key features include passive safety systems that maintain core cooling during power loss, and a double-cylinder containment vessel that suppresses radioactive releases in an accident, thereby significantly reducing potential offsite impacts compared with conventional reactors.

The introduction of AM technology will enhance supply-chain flexibility. Components that were previously difficult to manufacture—such as complex shapes or small-batch specialty parts—can be produced quickly, improving efficiency in maintenance and replacement. In particular, AM enables the production of high-strength, corrosion-resistant alloy components for in-core structures and cooling systems, reducing future procurement risks and strengthening both domestic and international supply chains.

The iBR also differs from small modular reactors (SMRs) currently being developed overseas. For example, GE Vernova and Hitachi Nuclear Energy’s “BWRX-300” emphasizes simplified design and cost competitiveness, with projects advancing in Canada and the United States. Holtec’s “SMR-300” features an underground reactor vessel to improve resistance to external events. In contrast, iBR adopts an approach of building upon proven BWR technology while incorporating innovative safety features, tailored to Japan’s regulatory environment and societal acceptance. While pursuing the same goals of safety and economic efficiency as SMRs abroad, iBR is positioned as a uniquely “Japan-type next-generation reactor” based on domestic technological heritage.

In this METI program, emphasis is placed not only on reactor design itself but also on the establishment of a sustainable supply chain. While heavy electric machinery makers are responsible for major equipment such as reactor pressure vessels and steam generators, fuel assemblies, control rods, and instrumentation will be procured from domestic suppliers. AM technology is expected to serve as a breakthrough that will encourage wider industry participation and new entrants, creating business opportunities particularly for companies with strengths in hard-to-machine materials and high-precision components.

Japan’s 7th Strategic Energy Plan, finalized in February 2025, clearly states that nuclear power is “indispensable for maximum utilization as a decarbonized power source.” With the aging of existing reactors, the development and deployment of advanced reactors with enhanced safety has become a key issue in balancing energy security with greenhouse gas reduction.

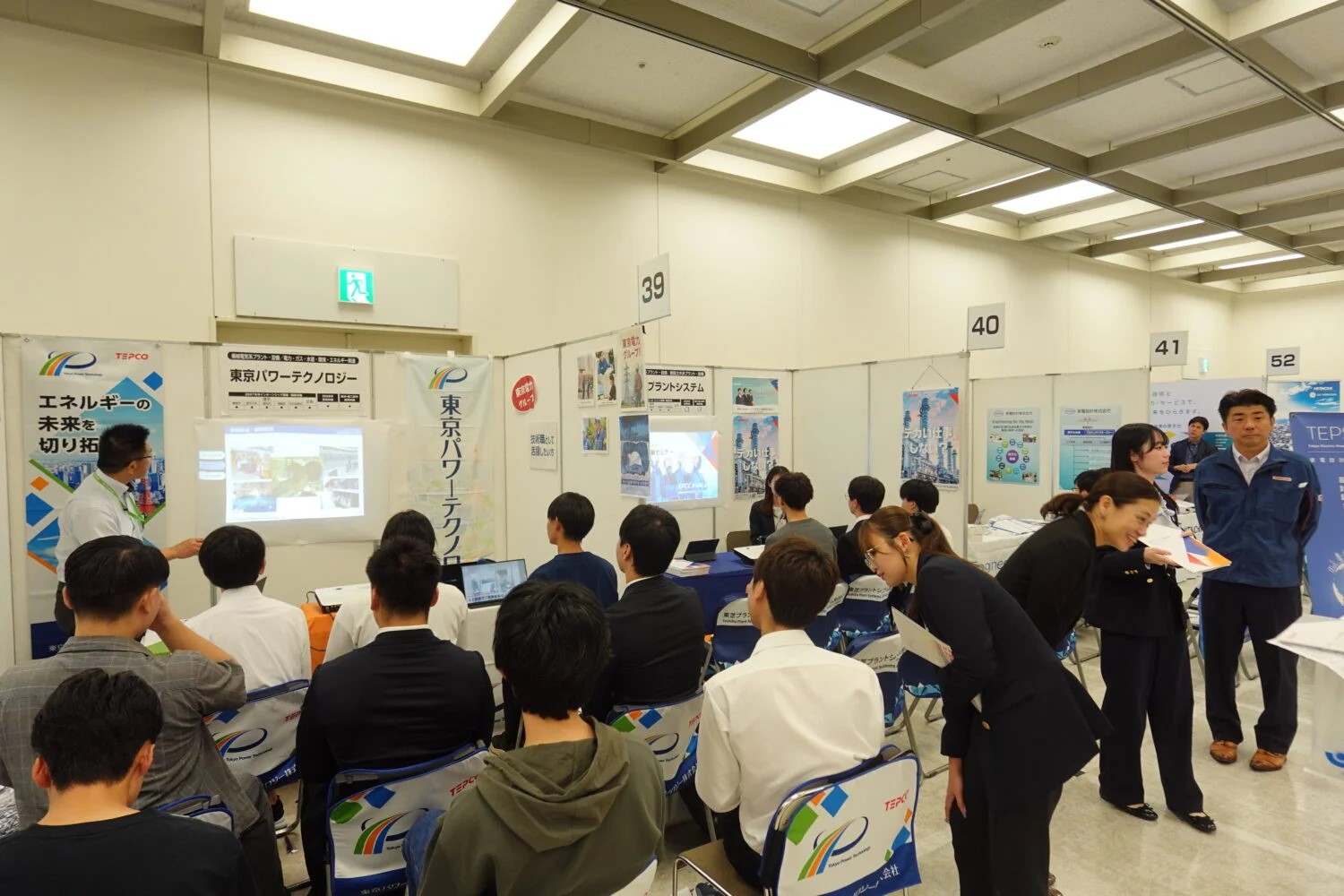

Since the Great East Japan Earthquake, stagnation in new construction has weakened Japan’s nuclear industrial base and human-resource pipeline. Toshiba views the current adoption as a turning point, aiming not only to advance reactor technologies but also to rebuild the supply chain and revitalize the nuclear industry. The company commented: “Toward realizing a carbon-neutral society, we will promote the development of next-generation innovative reactors while strengthening the industrial and human-resource base, thereby contributing to stable power supply.”

-013.jpg)

-049.jpg)

.jpg)