The session began with a presentation by ONO Akira, president of the Fukushima Daiichi Decontamination & Decommissioning Engineering Company, on the current state of decommissioning at Fukushima Daiichi. He also touched upon issues dealing with contaminated water at the site and the offshore discharge of treated water into the sea, among other related problems.

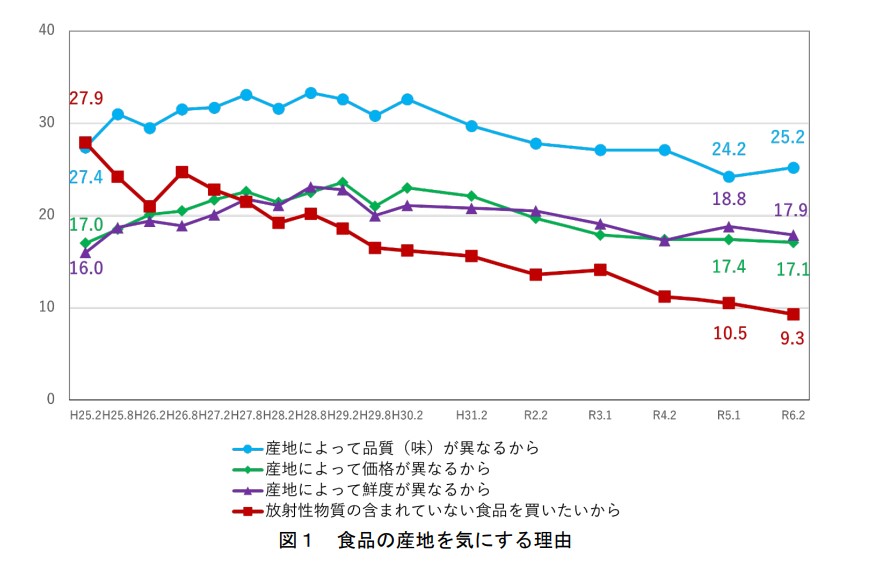

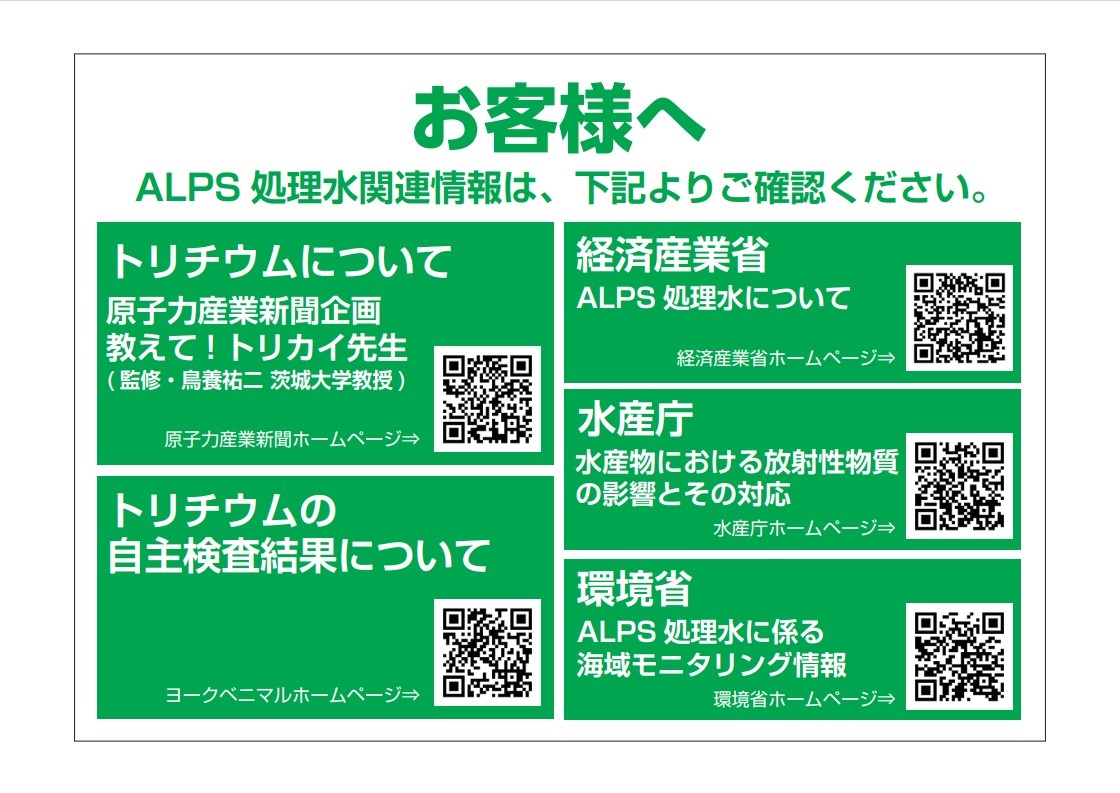

Ono said that the offshore release of water treated by the Advanced Liquid Processing System (ALPS) occurred first in August 2023, then four times during FY2023 (ended March 31, 2024). He added that the total volume of water discharged for that fiscal year was 31,145 cubic meters. The water was diluted by seawater each time prior to release, and he said that “no abnormality has been seen in tritium concentration after any of the discharges.”

The Tokyo Electric Power Co. (TEPCO) plans to discharge about 54,600 cubic meters of ALPS-treated water in seven different stages during the current FY2024.

Regarding the removal of fuel from the spent fuel pools at Units 1-4, although some fuel still remains at Units 1 and 2, it is slated to be removed in FY2027-2028 and FY2024-2026, respectively.

At Unit 1 (storing 392 fuel assemblies, including unused ones), in preparation for removal, a large cover embracing the reactor building is currently being installed, with completion scheduled for summer 2025 (date indefinite). At Unit 2 (storing 615 fuel assemblies, including unused ones), TEPCO plans to make an opening at the south side of the reactor building for inserting and withdrawing fuel handling equipment and devices, so as to prevent pollution diffusion and reduce occupational exposure.

The construction of a gantry and a front chamber for a crane and runway girder is also underway. Ono mentioned that TEPCO is considering the applicability of concrete casks—which have been shown to be safe overseas—for dry spent fuel storage.

In preparation for the removal of fuel debris, TEPCO plans to begin with a test removal of “a very small amount of debris” at Unit 2, where various investigations are furthest along. The robot arm to be used is undergoing mock-up tests and operator training, though a little more time is still needed for adjustments on it before it can be used at the site. An extendable telescopic guiding pike that was used successfully in investigations during FY2019 will be used as well. Ono said that the company “wants to start in October of this year at the latest.”

Investigations were carried out inside the pedestal (the foundation beneath the reactor pressure vessel) at Unit 1 in late February of this year to confirm the condition of fuel debris in the reactor containment vessel. Showing some recently obtained images, Ono said that four small drones and a snake-type robot relaying radio communications had been used during the investigations.

In preparation for increasing the scale of fuel debris removal, the focus, according to Ono, “will be on the partial submersion method (retrieving fuel debris exposed to the air, while pouring water), combined with the filling and solidification method (stabilizing fuel debris using filler and recovering the debris, structures and filler together by drilling or other means),” as proposed by the Fuel Debris Retrieval Expert Committee of the Nuclear Damage Compensation and Decommissioning Facilitation Corporation (NDF) in March 2024. TEPCO, Ono said, will develop designs in the next couple of years for actual use at the site.

Meanwhile, Ono also introduced TEPCO’s matching activities to promote participation by local industries in the decommissioning effort, toward achieving both reconstruction and decommissioning. By January 2024, around a thousand contracts had already been signed.

Concluding his presentation, Ono, looking back at the revival of local festivals and events and other steps toward reconstruction in the affected areas, said that “people are returning gradually, and areas are coming back to life.” TEPCO will continue working on decommissioning with top priority on safety, so that “residents can return to their hometowns without concerns,” he said.

A panel discussion followed Ono’s presentation, moderated by KAINUMA Hiroshi, associate professor of the Interfaculty Initiative in Information Studies at the University of Tokyo. There were four panelists, as follows:

- YOSHIDA Manabu, representative director of HAMADOORI 13

- SATO Taisuke, CEO of haccoba, Inc.

- ASANO Masami, CEO of Asano Nenshi Co., Ltd.

Kainuma, who hails from Iwaki City in Fukushima Prefecture, and who has authored many books and articles on the area’s reconstruction, had previously moderated the session on “Future Picture of Fukushima” at the 48th JAIF Annual Conference in 2015.

In his presentation preceding the discussion, he looked back at events in more recent years―such as the start of offshore discharge of the ALPS-treated water and the partial lifting of an evacuation order in Futaba Town―and said that while there are “new moves every year, there is a mountain of small issues yet to be resolved”―opening a path for discussions.

Yoshida Manabu—who comes from Okuma Town in the same prefecture—was working as a qualified architect on the premises of Fukushima Daiichi when the massive earthquake occurred in March 2011, and was later engaged in assessing the effects on local houses.

In 2021, concerned by the sharp decline in the population of Futaba County, he launched the HAMADOORI Phoenix Project to support young entrepreneurs in the district of Hamadori. In fact, the population of eight towns and villages in the country has plummeted from about 75,500 in 2011 to about 17,900 in 2024. A total of 18 enterprises have already been created under the project, some of which Yoshida introduced during the session. They included a kominka café in Kawauchi Village made from a Japanese traditional house and using local foodstuffs, a planned horse-riding club in Minami Soma City tied to the traditional local horse festival known as Soma Nomaoi, and a production field for kiwi fruit—a noted local specialty before the disaster—in Okuma Town.

The next presentation was by Sato Taisuke, a participant in Yoshida’s HAMADOORI Phoenix Project, and originally from Saitama Prefecture. Inspired by the coincidence that the earthquake happened on the same day as his birthday, he first underwent sake-brewing training in Niigata Prefecture, then opened a microbrewery and pub―called “haccoba Brew Pub”―in Namie Town, Minami Soma City.

Sato is an enthusiastic advocate for craft sake in the homemade doburoku style, as well as the “creation of new communities where young people can also get together.” He recently opened a brewery in Odaka Station on the JR Joban Line, giving a boost to tourism there. His next plan is to establish a sake brewery in Belgium.

Textile-maker Asano Nenshi Co., Ltd., led by Asano Masami, is based in Gifu Prefecture. With imported textile products predominant in Japan and itself in the difficult position of a subcontractor, the company was approached by the Ministry of Economy, Trade and Industry (METI) to help revive the domestic textile industry. In 2023, Asano opened a new factory in Futaba Town called Super Zero. Tying up with men’s clothing manufacturer Konaka to help in the reconstruction of the Tohoku region, the firm produced domestic T-shirts (Fukushima fukko kokusan T-shirts) last fall supporting Fukushima’s reconstruction. It has already hired additional employees this year and has recently started to accept factory tours by students.

In the panel discussion, the moderator Kainuma—who communicates actively with young people—pointed out several challenges for people settling in the local area, such as the lack of entertainment. In response to that, Asano referred to his recent experience of being interviewed by a foreign journalist, who asked him very pointedly, “Is the company confident that its employees will find, and be able to have, satisfying lives? Can it promise them that?” Asano then said that the journalist, having talked to some of his young employees, seemed to have been convinced. “The world still misunderstands Fukushima,” Asano said. “It needs to come here and see us for itself.”

mini.jpg)

.jpg)

.jpg)